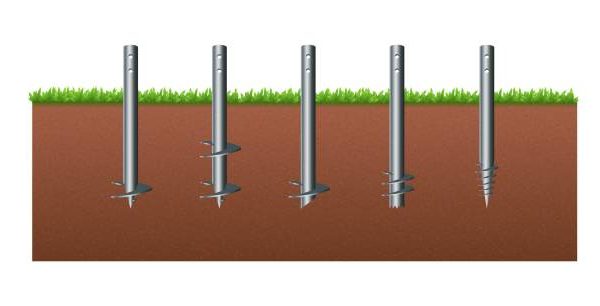

When it comes to piling in construction, efficiency is paramount. Piling, the process of driving deep foundation elements into the ground to support structures, requires precision and stability. One crucial element that significantly enhances piling efficiency is Bentonite. This versatile material offers numerous benefits throughout the piling process. In this article, we will explore five ways Bentonite enhances piling efficiency and how you can leverage it for successful construction projects.

1. Utilizing Bentonite in Piling: Preventing Excavation Collapse Before Concrete Pouring

Before pouring concrete, ensuring that the excavation remains stable is critical. Bentonite comes into play here by creating a stable slurry that prevents the collapse of the excavation walls. This slurry effectively supports the excavation, allowing you to work without the fear of walls collapsing and disrupting the process. This initial step sets the foundation for a smooth and efficient piling operation.

2. Managing Excavation Stability During Concrete Piling

During the process of pouring concrete into the pile, Bentonite continues to play a pivotal role. It acts as a slurry wall, maintaining the integrity of the excavation while concrete is poured. This prevents voids or gaps from forming around the pile, ensuring that the concrete fully encapsulates the pile and maintains structural integrity. This step is crucial in guaranteeing the stability and load-bearing capacity of the pile.

3. Key Factors Influencing Soil Stability

Understanding the factors that affect soil collapse during piling is essential. Bentonite addresses many of these factors effectively. It’s particularly beneficial in scenarios where the surrounding soil is prone to collapse due to its cohesion and suspension properties. This mitigates the risk of soil caving in, reduces project delays, and ensures the safety of the construction crew.

4. Enhancing Soil Stability with Bentonite Slurry

4. Enhancing Soil Stability with Bentonite Slurry Bentonite’s ability to stabilize soil is a game-changer in piling projects. By creating a Bentonite slurry, you can improve the stability of the surrounding soil. This not only prevents soil collapse but also enhances hole stability, making it easier to maintain the desired pile diameter and depth. The result is a more efficient piling process with minimal disruptions.

5. Types of Bentonite for Piling Applications

It’s essential to note that not all types of Bentonite are ideal for piling applications. While Bentonite is available in various forms, including sodium Bentonite and calcium Bentonite, the choice depends on the specific soil conditions and project requirements. For piling, sodium Bentonite is often preferred due to its excellent swelling and sealing properties. It effectively prevents water infiltration and maintains stability in the excavation.

6. Where to Buy Effective Bentonite

To harness the benefits of Bentonite for your piling projects, it’s crucial to source high-quality Bentonite. SEPCIO, a leading manufacturer of Bentonite in the UAE, offers a wide range of reliable Bentonite products, including those suitable for piling applications. Their products are known for their quality and effectiveness in construction applications. You can explore their offerings here.

In conclusion, Bentonite is a valuable asset for enhancing piling efficiency. Its ability to prevent collapse, stabilize soil, and maintain excavation integrity significantly contributes to successful piling operations. Whether you are facing challenging soil conditions or simply aiming for a more streamlined piling process, Bentonite is a go-to solution. Don’t forget to choose a trusted supplier like SEPCIO to ensure you get the best Bentonite for your construction needs.